Kalmar Ottawa’s third generation of electric terminal trucks or yard trucks will help improve the eco-efficiency of your operations while maintaining the highest levels of productivity and safety. With a range of modular battery options and charging solutions, we can work with you to design a solution that will deliver for your yard, terminal or distribution centre.

Eco efficiency built in

Your electric terminal tractor will produce zero carbon emission at source, making them cleaner and safer to operate in your yard, terminal or distribution centre. Getting an electrically powered yard truck is only the start of your eco-efficient journey. One that we will be with you every step of the way.

Three big benefits

There are three distinct differences and many small ones to our new generation of electric terminal tractors for you to benefit from:

- Charge times reduced. Our first big change has been to incorporate a DC FastChargeTM System, which has allowed us to decrease our charge time significantly.

- Electric motor. The second is that we have eliminated the transmission from the driveline, moving to a direct drive solution where the electric motor is powering the drive axle, reducing the complexity of the driveline.

- Ability to operate in extreme temperatures. Thirdly, we have included an Active Thermal Management System, which will allow your electric terminal tractor to operate optimally at full power in extreme temperatures. The system keeps your core battery temperature between 77-86˚F for optimal performance even when the temperature outside gets down to -22˚F or up to 122˚F.

When all brought together you have the Kalmar Ottawa T2 EV Electric Terminal Tractor which can be charged quickly and easily, will operate optimally in extreme weather conditions, is easier to service and maintain.

Modular by design

Batteries and chargers are a big part of your overall investment in your electrically powered yard truck making it critical that you get a solution that is matched to your operational requirements, which is why Kalmar has taken a modular approach to our battery and charging solutions.

There are different charging solutions available with charging capacities up to 150kW and three different Li-ion battery capacities to choose from.

Our battery solutions all come with a 6 year/2800 charge cycle warranty*. Kalmar can help you work out which battery option and charging solution is right for your business based on your current work cycles.

Managing your power

Kalmar’s Battery Monitoring System continually monitors the voltage, temperature, coolant and current flow of your battery solution to ensure that it operates optimally over its lifetime. This system also controls the charging of the batteries by utilizing regenerative breaking, sending recovered energy back into the battery packs making sure you are using the power available as efficiently as possible.

Our battery solutions all come with a 6 year/2800 charge cycle warranty*. Kalmar can help you work out which battery option and charging solution is right for your business based on your current work cycles.

*First life measured as 80% capacity left in the battery.

For complete peace of mind.

All Kalmar Electric Terminal Tractors come with a 3 year/6500 hour warranty on major electric components, and a 6 year warranty on the batteries. Kalmar Ottawa also offers a full range of service packages and genuine parts to keep your terminal tractor operating optimally, thus minimizing downtime.

Link to Kalmar webpage to learn more about the T2 EV

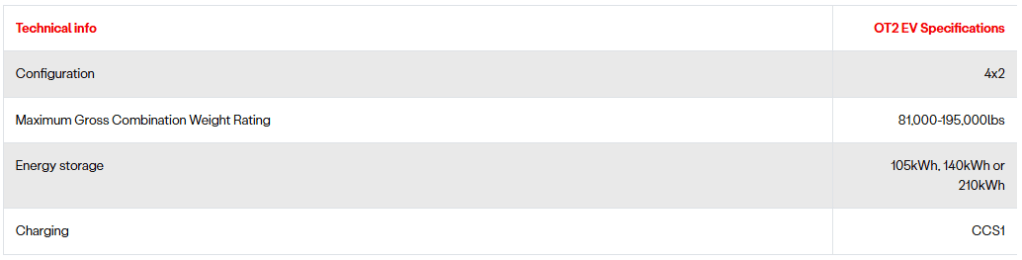

Kalmar T2 EV Technical Information

Take the T2 EV for a Test Drive!

For more information, a demo or pricing on a new Kalmar T2 EV, please contact us at 800-322-5438. Cal-Lift is your source in California, Arizona and Nevada for Kalmar equipment, service, rentals and parts.