SE25-SE35 S-Series

5,000lb. / 6,000lb. / 7,000lb.

Solid Pneumatic Tires

Electric Forklift

Introducing the all-new CLARK SE25-35, the latest addition to the CLARK S-SERIES lineup of SMART, STRONG, and SAFE forklifts! With a capacity range of 5,000-7,000 pounds, an integrated 80V Lithium-Ion battery, and advanced safety features to keep your operations running smoothly and safely shift after shift, the SE25-35 continues the legacy of the S-SERIES line.

Ideal for customers that need to seamlessly transition from indoor to outdoor spaces, the SE25-35 provides all of the ergonomics and functionality of an IC truck without the harmful emissions and operation volume.

SE25-SE35 S-Series Electric Features

SMART – The SE25-35 integrates SMART features including:

- 6 inch” LCD SMART Dash

- On-Board Diagnostics Through Dash Display Screen

- ZAPI Controllers for Advanced Control and Communication

- Three Selectable Performance Modes and Turtle Mode for Ultimate Operational Control

- Integrated 80V Lithium-Ion Battery with Diagnostics in SMART Dash

- Vertical Mast System Allows for Fork Leveling Regardless of Tilt

STRONG – The SE25-35 builds on the CLARK Built to Last commitment with STRONG features including:

- Full Capacity Range of 4,000 to 7,000 Pounds, for a Solution That Fits all Needs

- Integrated Lithium-Ion Battery is Practically Maintenance Free, With No Watering Required

- Fully Welded, Heavy Gauge Frame

- Six Roller Carriage with Side Thrust Rollers Improves Stability and Minimizes Mast Deflection

SAFE – Safety is at the core of all CLARK products, and the SE25-35 continues that legacy with excellent SAFE features including:

- Self-Activating Parking Brake Engages When Truck Comes to a Rest and Operator Leaves the Seat

- Wet Disc Service Brakes Require Less Maintenance and Have Lower Overall Cost of Ownership Compared with Standard Drum Brakes

- Nested I-Beam Mast is Durable and Reliable

- Twin Primary Cylinder Design in Mast Provides Better Operator Visibility and Improved Safety

- Counter Rotating Wheels Allow SE20-35 to Achieve Zero Turn, Reducing Turn Radius and Allowing Operators to Navigate Smoothly

- Curve Cutback Feature Allows for Speed Control When Navigating Turns

- Low Profile, Wider Truck for Increased Stability

NEW FEATURES

- 6” SMART Dash Display with Audible and Visual Warnings and Lithium-Ion Battery Integration

- Password Protected Access to Advanced Truck Settings

- Three Performance Modes:

- Economy, Standard, and Power

- Improved Operator Ergonomics

- Wider Floorboard for Improved Operator Ergonomics

- Updates to Motor Design to Reduce Operational Noise

VERTICAL MAST SYTEM

The CLARK Vertical Mast System allows operators to pick product with confidence, by ensuring forks are level regardless of the degree of tilt on the mast.

ERGONOMICS

- CLARK-Standard Vinyl Full Suspension Seat

- Hood Mounted Levers in S-SERIES Styling with Forward/Reverse and Horn Button Options on Levers

- Ergonomically Designed Pedals for Optimal Ease of Operation

- Optional Fingertip Controls Allow for Improved Operator Ergonomics

- Optional S-SERIES Style Cabin with Heat

SOLID AND VERSATILE

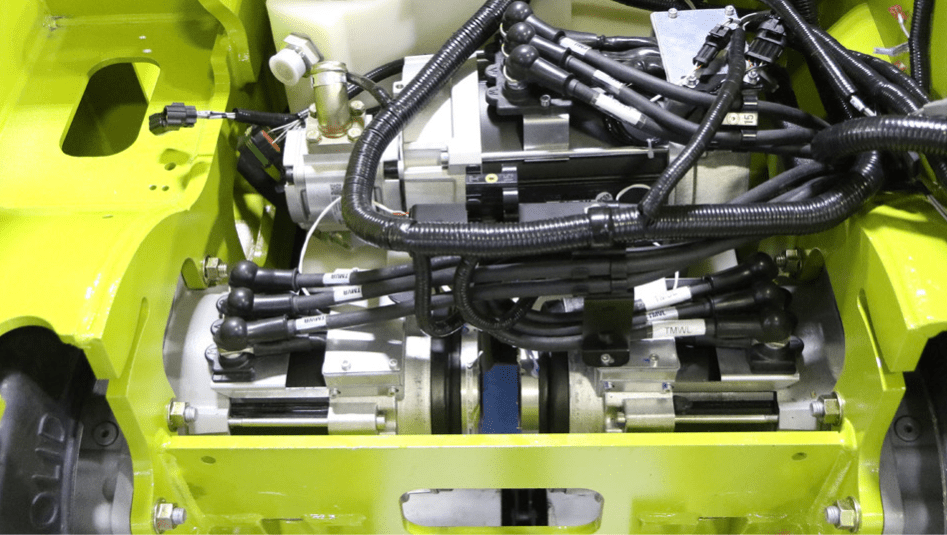

- Field-tested and strength-proven drive unit, steer axle, and upright

- Welded heavy gauge frame provides lasting durability

- CLARK Nested I-Beam mast designed for stability and longevity

- Full capacity range of 4,000 to 7,000 pounds to accommodate a wide range of applications

INDOOR & OUTDOOR APPLICATIONS

Increase your productivity while minimizing cost with the SE25-35. With the ability to seamlessly transition between indoor and outdoor spaces, operations no longer need two trucks to accomplish what the SE25-35 alone. The low profile, wide stance, and durable composition of the SE25-35 makes it ideal for operations with paved outdoor spaces, as well as indoor manufacturing facilities. The optional CLARK S-SERIES heated cabin allows operators to transition from indoor to outdoor operations even in harsh weather conditions.

VIDEOS

MORE INFORMATION

For more information, a demo or quote on a new SE25-SE25 Electric forklift from CLARK Material Handling, please contact us at 800-322-5438.