CLARK’s SEC20-35, a 4,000-7,000 pound four-wheel electric forklift is the latest addition to the S-SERIES family, the SEC20-35 combines all of the SMART, STRONG and SAFE features you’ve come to expect from the S-SERIES family with none of the emissions of a standard IC truck. Featuring an ergonomic operator compartment, strong components, and a true 7,000-pound capacity—a first for CLARK four-wheel electric forklifts—the SEC20-35 is the perfect choice for a wide variety of indoor applications, including warehouses, manufacturing facilities, food and beverage operations, and more! Download the brochure for all the details.

SMART

The high-resolution interactive LCD dash display on the SEC20-3 allows operators to stay constantly informed about the truck’s performance. New ZAPI ACE3 controllers allow for advanced control and communication. Three selectable performance modes, along with a turtle mode feature, allows for greater flexibility and customization per application.

STRONG

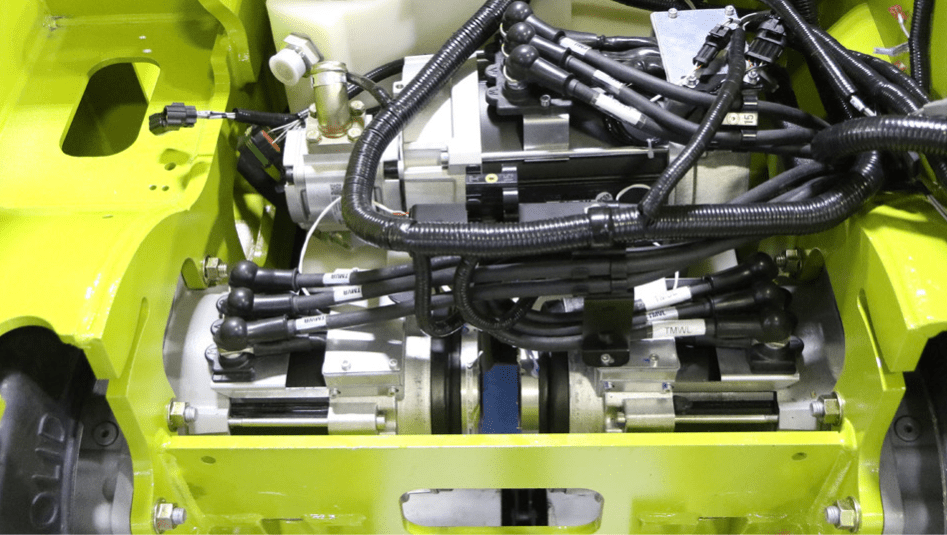

With the SEC20-35, durability and reliability are never in question. With a capacity range up to 7,000 pounds—a CLARK first for electric four-wheel trucks—and key components designed to withstand full capacity, the SEC20-35 can tackle any challenge in its path. The rear-hinging hood provides durability and allows for easy service, and the thick, durable front fenders provide strength to the frame of the truck. The steel sump tank dissipates heat faster, prolonging hydraulic oil life, ensuring your SEC20-35 is Built to Last for years to come.

SAFE

Safety is a cornerstone of all CLARK products, and the SEC20-35 is no exception. The integrated Dampening Block Stability increases stability and durability in the lift truck. The standard Performance Enhancement Package utilizes a cutback switch on the mast, reducing tilt and travel speeds when the forks are fully loaded and lowered, improving operator and pedestrian safety. Additional optional safety equipment includes load weight indicator, seatbelt interlock, and more!

ADVANCED ERGONOMICS

The ergonomically designed operator compartment promotes greater operator comfort and efficiency, with a spacious floorboard, small steering wheel diameter, hood-mounted levers, cowl-mounted SMART dash, and comfortable full-suspension vinyl seat. The accelerator and brake pedals are also optimally positioned for smooth transitions, reducing operator fatigue.

SOLID AND VERSATILE

The welded heavy gauge frame provides lasting strength and consistency in the operation of the truck. A CLARK standard, the nested I-beam mast on the SEC20-35 was designed for longevity and stability, allowing for a true 7,000-pound capacity on the SEC35. Finally, all major components for the series were designed to withstand the full 7,000-pound capacity, ensuring that no matter which capacity you need, the components can tackle any job with ease.

For more information, a demo or quote on CLARK’s new SEC20 – SEC35 please contact us at 800-322-5438. Visit our CLARK showroom to see all the CLARK products available at our Southern California branch.