8,000lbs. – 12,000lbs. Capacity

Pneumatic Tire

LPG/Diesel Engine Options

Building on over 100 years of lift truck innovations, design and industry firsts. The evolution continues…. the CLARK S-Series, the next generation of lift trucks. These models, designed for distribution, manufacturing and warehousing of all types, are suited for the toughest applications.

SMART

The interactive dash on the S40-60 provides audible and visual warnings to operators, and is password-protected, allowing only authorized users to change truck settings. The on-board diagnostics allow operators to quickly and efficiently address any issues, while the engine and powertrain protection helps safeguard your truck against overheating. And, with two selectable performance modes on the LPG engine, operators have greater flexibility to optimize the performance of the truck in their application.

STRONG

With a fully welded heavy gauge frame, the CLARK-standard and field-tested nested I-beam mast, and external side thrust rollers, the S40-60 is durable, reliable, and STRONG. Stability is further improved with the optimal center of gravity, allowing the truck to maintain capacity and balancing the truck when fully loaded.

SAFE

The S40-60 series is designed to promote operator safety, with several key safety features built into the truck. The Nested I-Beam mast provides greater stability, and the lowered cross bar on the S40 provides a wider field of vision, allowing operators to navigate with confidence. The Automatic Parking Brake and SMART Dash with audible and visual warnings are both standard on the S40-60, further improving operator safety.

ADVANCED ERGONOMICS

Advanced ergonomic features on the S40-60 include a standard adjustable full-suspension vinyl seat, hood mounted levers with low input force required, a small diameter steering wheel with a standard spinner knob, adjustable steering column, and spacious floorboard which can accommodate operators of all boot sizes. The design of the S40-60 has been optimized to reduce vibration and noise in the operator compartment. And the optimized initial step height and convenient grab handle on the overhead guard allows for easy entry/exit on the truck as well.

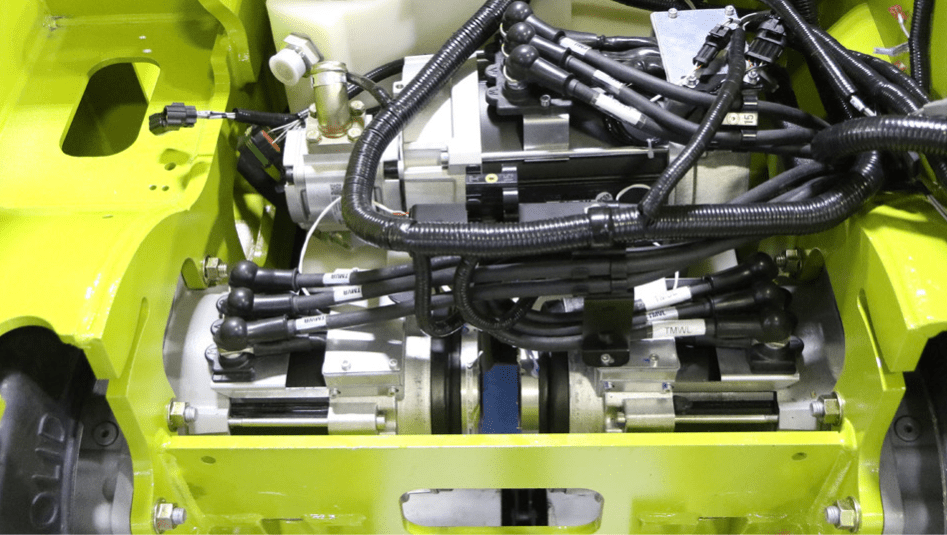

KUBOTA LPG & DIESEL ENGINES

KUBOTA LPG AND DIESEL ENGINES

- Kubota WG3800 LPG Engine:

- CARB and EPA Certified

- Peak power of 85.3 hp is achieved at 2200 rpm

- Tier-4 Final/Kubota V3800 Diesel Engine

- No regeneration (burn off) cycles

- Diesel Oxidation Catalyst

- Peak power of 74.3 hp is achieved at 2200 rpm

S40 – S60 FEATURED VIDEOS

For more information, a demo or a quote, please contact us at 800-322-5438.